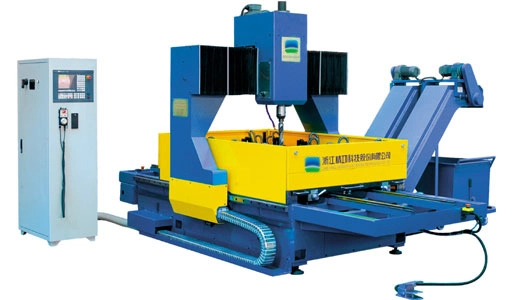

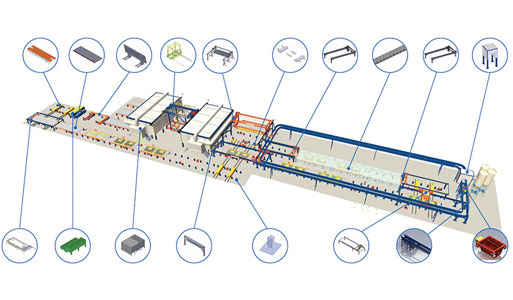

Box-shape Column Welding Line consists of a box assembling machine, GPW welding machine, submerged welding machine, electro slag welding machine, surface milling machine, moveable driving machine, turn over the machine, and conveyors. It can lower working strength and improve working efficiency.

This line is suitable for work pieces section (400-1500)mm X (400-1500)mm, thickness 16---80mm, length 4000---15000mm, Max weight of one piece can be 20T, Single working shift one year can produce about 30,000T. Max. capacity of this line is about 30,000T per year, but it varies according to different machine configurations and specs.

It is extensively used in large bridges and high steel structure buildings. The box column welding machine has earned 2 patents of the utility model.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China