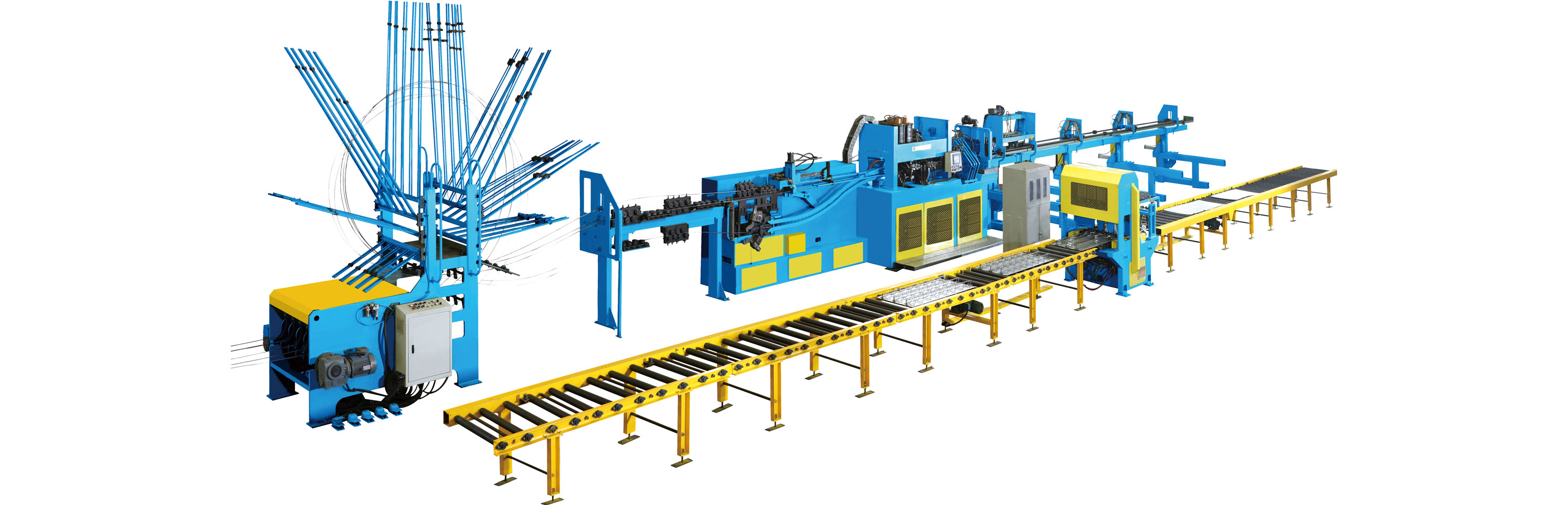

This production line consists of 5pcs of vertical steel bar decoiler, pre-straighten device, steel bar storage device, steel bar second straighten device, first-quarter steel bar rectifies device, steel bar bending device, steel bar transmission device, 200mm step distance fixed position device, steel bar welding device, web member footing bend device, steel bar cutting device, stacking device, electric system and hydraulic system, etc.

After calculation, the electricity cost per square meter for the final product is less than 1 Chinese Yuan. And we have two types of layout for the whole line, straight line or angle line, that we can design the layout as your plant.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China