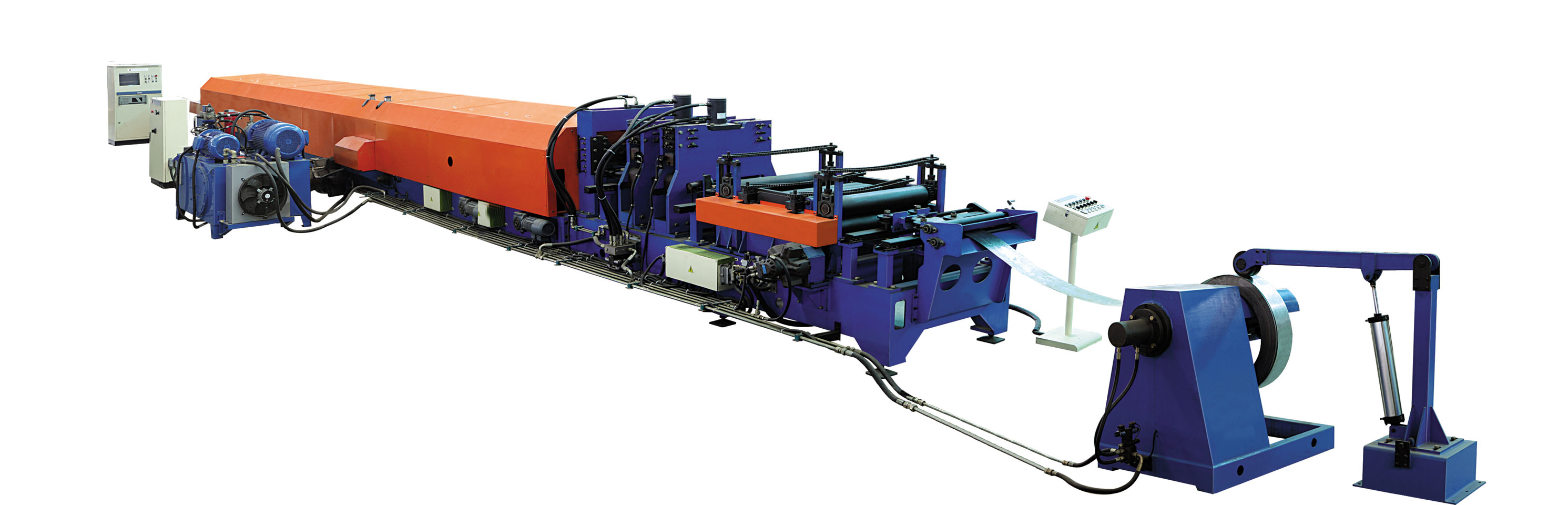

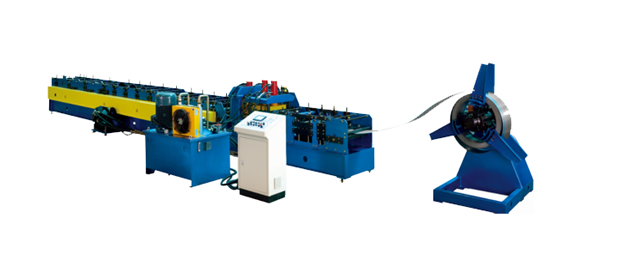

C&Z changeable purlin automatic machine can produce both C-shaped steel purlin and Z-shaped steel purlin in one machine quickly. And the machine can auto-change the profile and specifications automatically. The C-shaped steel purlin has good flatness, anti-bending, and anti-pressing properties. The Z-shaped steel purlin can reverse install that can increase the structural efficiency of the connecting point, decrease the thickness of the used steel, shorten the construction cycle, and add the benefit. They can be used as the main supporting structure and are widely used in large and medium scale factory buildings and civil constructions.

The C&Z automatic changeable purlin machine manufactured by Zhejiang Jinggong Science and Technology Co., Ltd. changed the situation of using two different machines to produce and manually changing specifications. This machine can produce different specifications of purlin automatically. It was known for its safe and high-efficiency workflow.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China