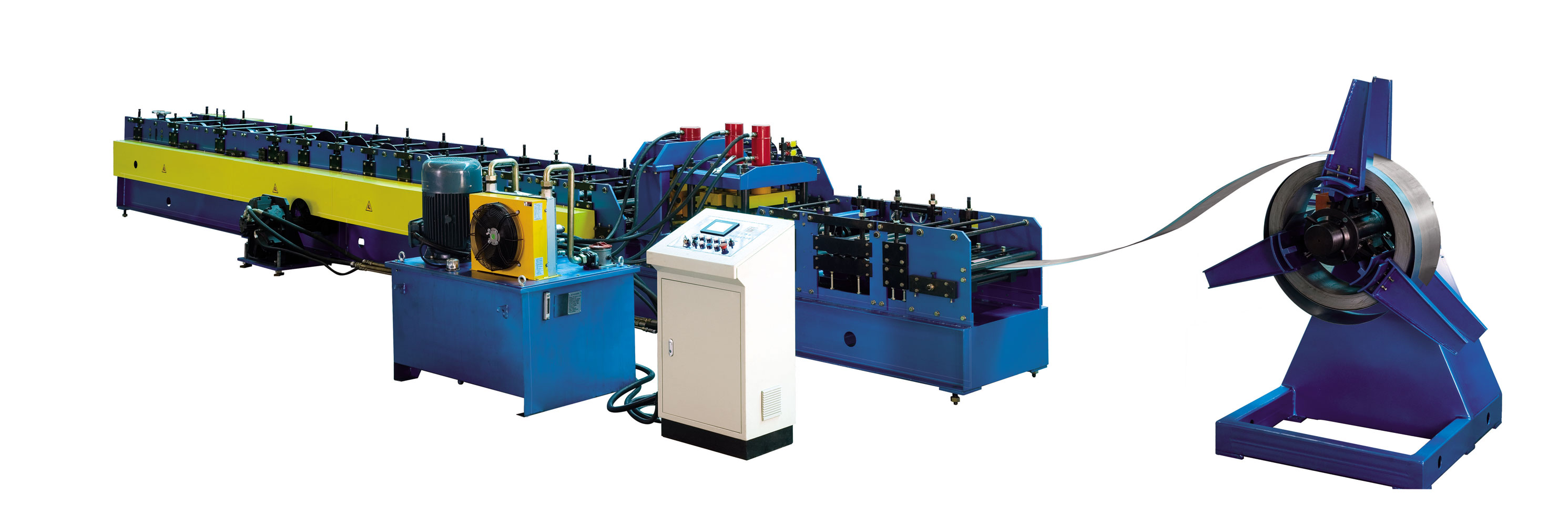

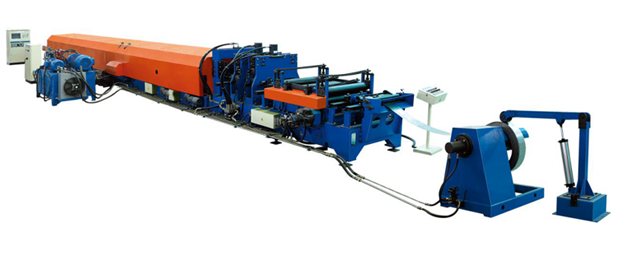

The C/Z purlin roll forming machine can form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C type or Z type purlin. Various specifications of purlin can be produced by changing the spacers.

The technical flow process of C/Z purlin roll forming machine: decoiling → feeding steel strip → sheet leveling → punching to length → cut to length → roll forming → run out table.

With 53 years' experience, Jinggong is specialized in manufacturing high-quality C Z purlin roll forming machine, feel free to contact!

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China