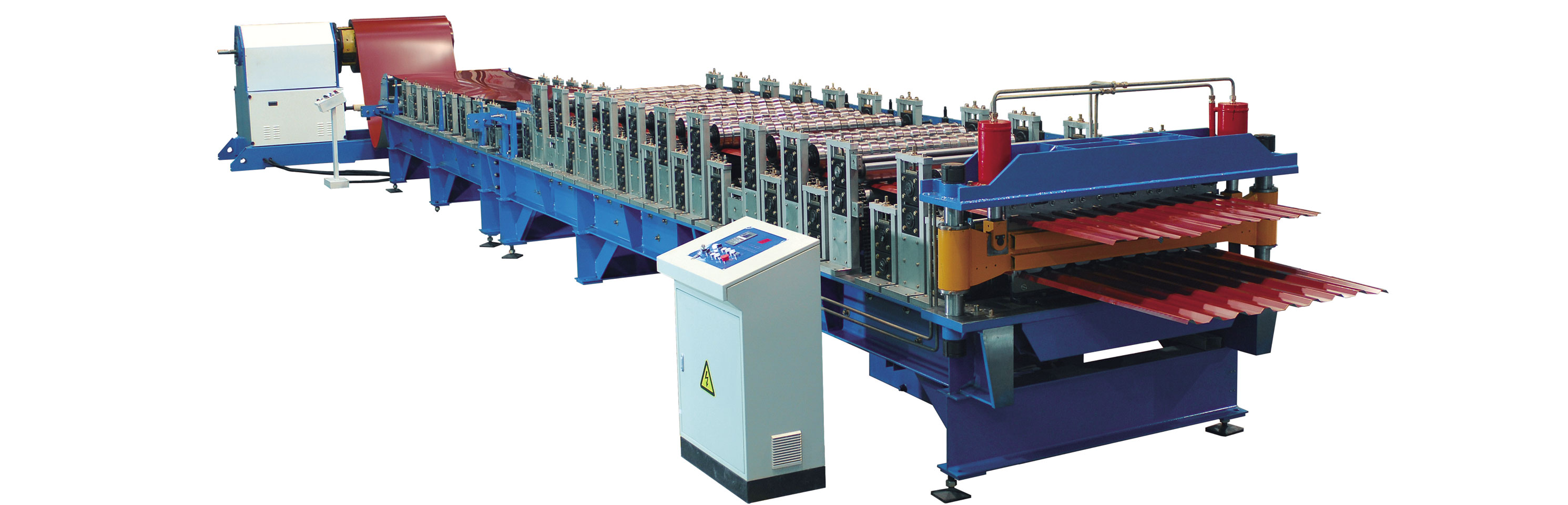

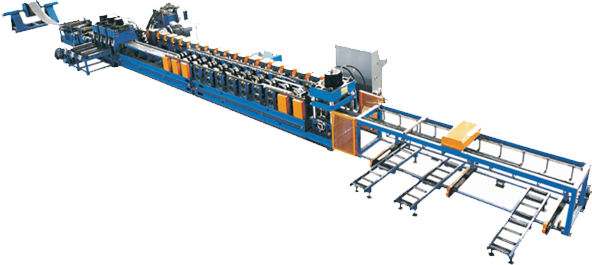

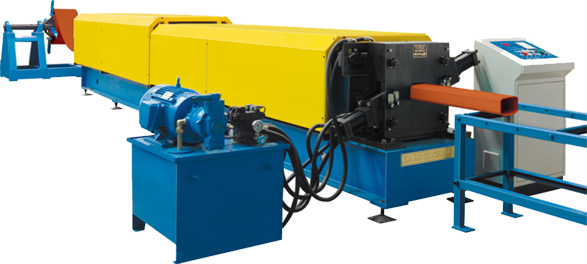

Main Technical Features Of High Speed Roll Forming Machine

1. Adopt independence guide post supporting wall plate and inside the transmission chain, the rollers are treated with nitriding and polishing.

2. Setup the flat sheet pre-cutting equipment to avoid waste of raw material.

3. Procedure control and encoder measuring the length, it will automatically cut to length.

4. Adopt procedure control stacker which will automatically stack, take count and move out the products.

Technical Flow Of High Speed Roll Forming Machine

Decoiling→feeding the steel sheet→flat sheet cutting→side guiding→add lubrication→roll forming→cut to length→products stacking→move out products.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China