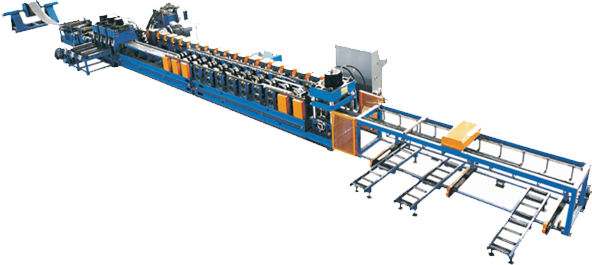

Technic Flow Of High-Speed Tile Forming Machine

Decoiling→guiding and feeding→roll forming→pressing→cut to length→run out table

Main Components of High-Speed Tile Forming Machine

Uncoiler

Cantilever-type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment. The pressing-arm hydraulic driven power is optional. All electrical parts and hydraulic parts are installed inside of uncoiler frame.

Roll forming

Roll forming system consists of guiding device, machine base, transmission parts. and roll forming rollers, etc. The filming and pre-slitter device is optional.

Punching

The punching system adopts hydraulic type punching, which works stably and without scratch. The single punching or twin punching is optional.

Post-shearing device

Post-shearing device adopts frame type hydraulic shearing. The panel is cut stably and can avoid distortion. This design don't have any scrap in the process of cutting.

Hydraulic system

Hydraulic system is installed inside of machine base. The design is reasonable and compactly.

Controller

It adopts Mitsubishi PLC and frequency inverter adjustment to realize fully automatic operation. Operator can set parameters such as badges, length of panels quantities in the touch screen.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China