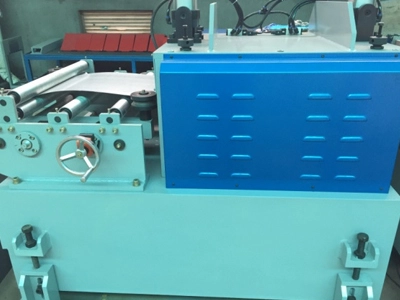

1)Adopts PLC control technology, frequency adjust speed technology, realize the automatic production.

2)System provide good man and machine screen, which can set the bataches, plate length, and quantities.

3)Operation type: Touch screen+button.

4)Encoder calculate the number, which has calculation and measure the length function.

5)The signal switch and measuring element are imported

6)PLC adopts MITSUBISHI or similar brands

7)Frequency converter adopts MITSUBISHI or Danfoss or similar brands.

8)Encoder adopts OMRON or similar brands.

9)Low voltage electrical part adopts Schneider.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

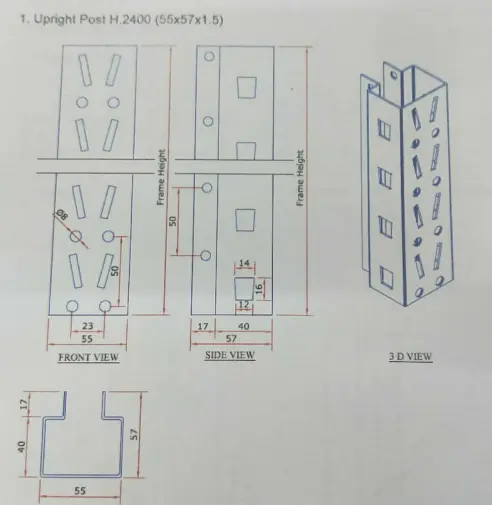

Parameters:

Parameters:

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China